products

Products & Services

AC Motor Drive - Inverter

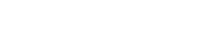

RM6S Series Inverter

ID:RM6S

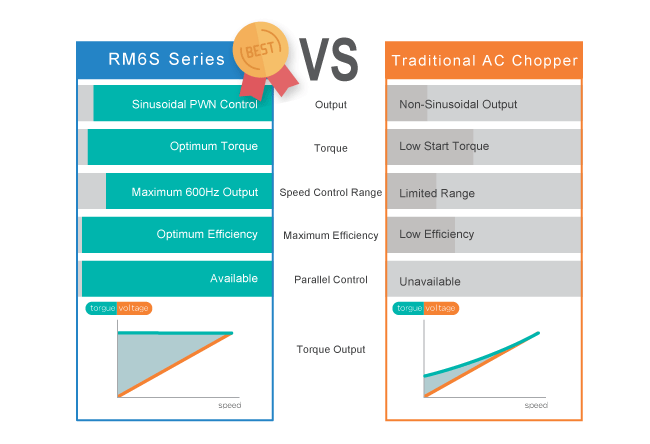

The RM6S series inverter, with its compact appearance and user-friendly operation interface, showing the inverter design process capability. It is specially developed for single/three-phase power field of small horsepower, divided horsepower motor frequency conversion control application. The core has non-sensor vector control technology, supports IM, SPM, IPM and other mainstream motors of high-performance operation control, suitable for fans, pumps, conveyor belts, small electric hoist, processing machinery, food machinery and other applications.

The RM6S series inverter has a capacity range of 0.125kW ~ 1.5kW, with excellent overload capability and performance, and is available in two types: panel-mounted and wall-mounted, to meet the control needs of various applications.

The RM6S series inverter has a capacity range of 0.125kW ~ 1.5kW, with excellent overload capability and performance, and is available in two types: panel-mounted and wall-mounted, to meet the control needs of various applications.

Products InfoInformation

Control Features

Highly Stable Speed Accuracy

The steady-state error of the speed can be less than 0.05%, which can achieve the needs of high precision.

High Torque Output

The non-sensor vector control technology enables the motor to reach 200% of the rated torque at very low speeds, making it suitable for equipment with high starting torque and heavy load operation.

Fast Reaction Time

The speed of the motor will decrease at the moment of load. High responsiveness enables the motor to return to the set speed in a short time when it is under load.

Applications

Fluid machines

fans, pumps, extractors, fans...etc.

Industrial equipment

food packaging, pharmaceutical equipment, conveyor belts, feeders, vibrators, grinders, balers, woodworking machinery, etc.

Application Functions

- Built-in PID control with auto-sleep and wake-up functions for pressure and temperature control applications. The PID function can also be opened independently for other devices.

- Built-in 16 sets sequence control for cycle/time/direction/time settings.

- The SPEC key on the keypad can be set to simulate the functions of the digital input terminals, and 60 functions can be switched, such as forward and reverse rotation, primary and secondary frequencies, secondary acceleration and deceleration...etc.

- Two sets of independent motor parameters can be established, and a single inverter can switch and control two motors of different specifications.

- Parameter password lock and parameter lock function ensure that parameters cannot be viewed or changed arbitrarily.

- Built-in RS-485 Modbus communication interface.

Safety Function & Prediction and Maintenance

Safety Function

- UL 508C, UL61800-5-1 and CSA C22.2 No.274-17 safety certification.

- The design is in accordance with CE certification and an optional EMC filter can effectively suppress electromagnetic interference and meet the electromagnetic compatibility requirements of various countries.

Prediction and Maintenance

- PTC motor overheat protection function, automatic overheat warning or tripping protection.

- Records sush as operating hours and power transmission hours can be queried, which is convenient for planning maintenance and inspection.