ODM & OEM

From design and development, material procurement, printed circuit board, OEM, incoming material inspection, material storage and inventory management, circuit board assembly, functional testing, semi-finished mechanical parts assembly, one-stop integration services, etc., with complete integration experience, each session will always uphold the professional and careful attitude, strictly checking customers’ products, and also provide professional circuit design, software and hardware integration of customized service solutions We also provide professional circuit design, software and hardware integration customization service solutions and PCBA OEM services to provide you with complete and tested. electronic module products with production records, looking forward to establishing two-way communication to customers and providing a full range of professional OEM services.

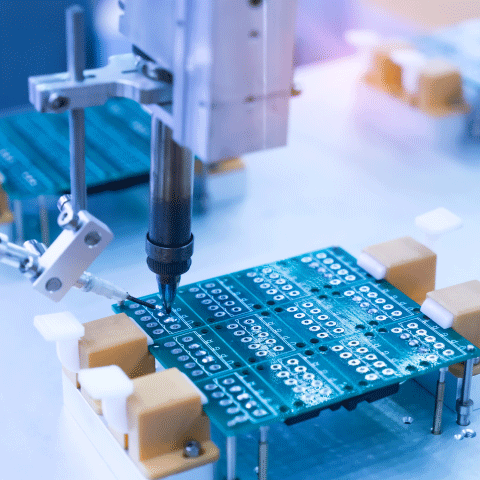

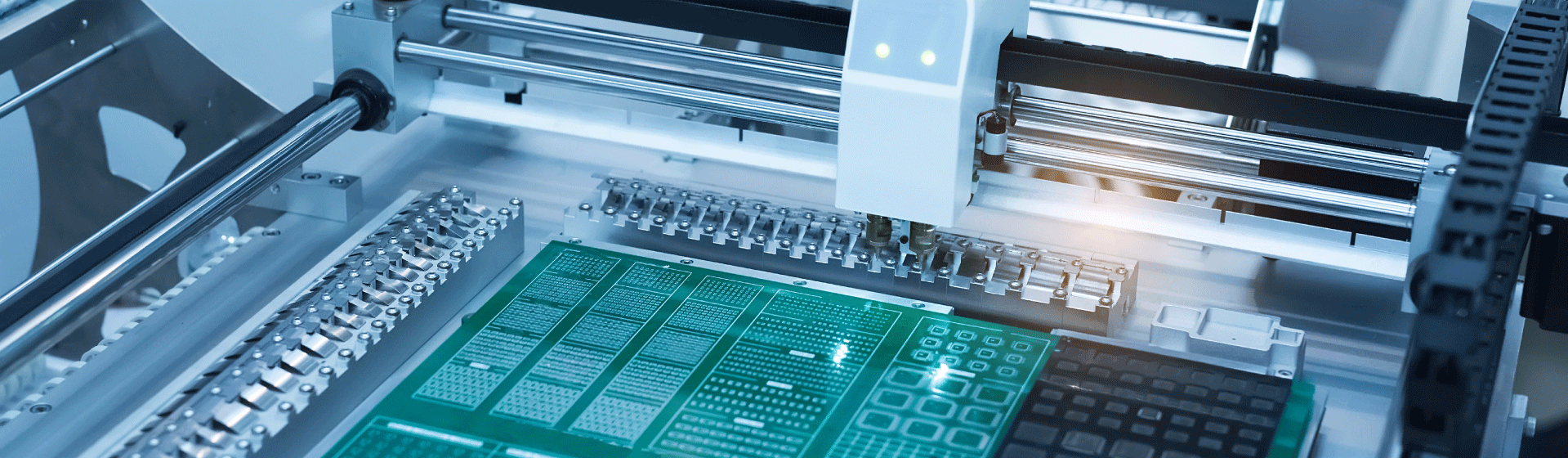

Excellent Manufacturing Capability

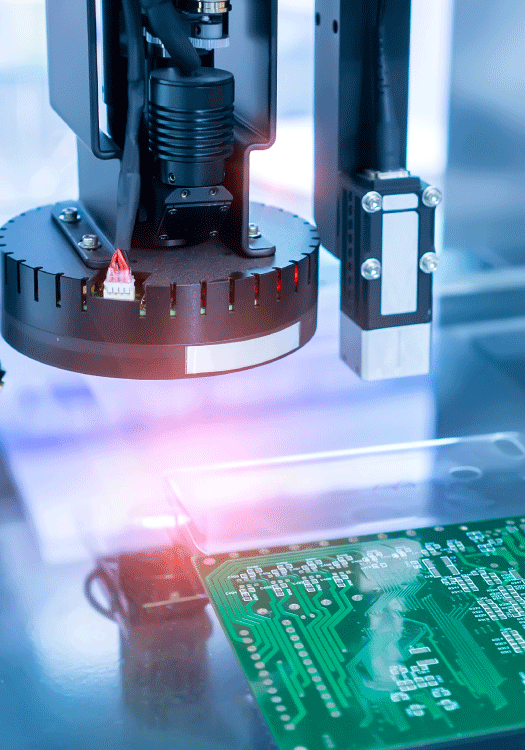

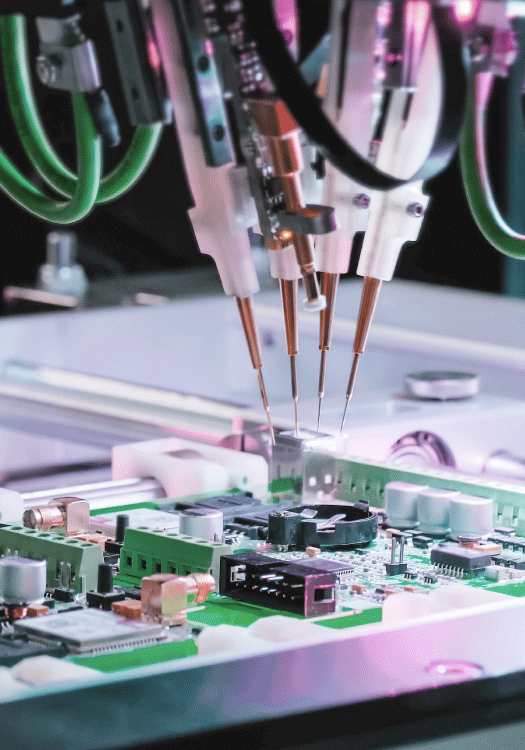

We have highly skilled and experienced professional technicians and complete manufacturing service facilities for mounting circuit boards, various types and sizes of components and related processes, such as conformal coating and dispensing, in automatic and semi-automatic equipment.

Material Storage Management System

SMT component management is integrated into SMT Reel Storage System management system, control material FIFO, production history traceability, expiration date indication and inventory level . There is also a constant temperature and humidity storage area to control special materials, such as moisture sensitive devices.

Material procurement common platform

Integrate material selection experience and procurement channels to maintain product quality and stable supply.

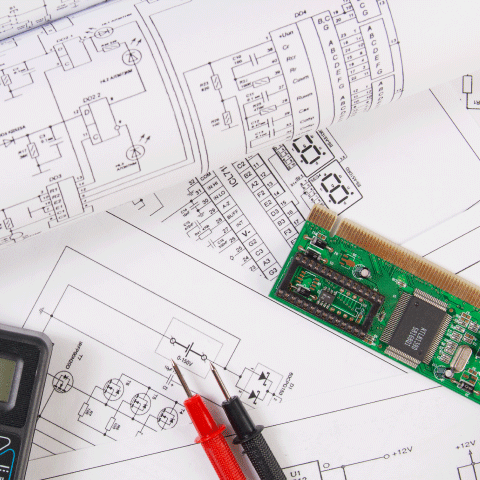

Customized Design

With more than 30 years of design, R&D and mass production experience, our professional R&D team combines software design, hardware design, mechanism design, Layout, testing and verification, and biotech process technology to provide the most complete product feasibility and design energy.

Customer Needs

Design and Development

Prototype Production

Customer Validation

Quality Control

PCBA Mass Production

After Sales Service

Customer Needs

Combining the complete technical resources of software, hardware, mechanism and circuit layout, we provide customers with comprehensive design consultation to confirm their complete needs.

Design and Development

Our R&D team has experience in designing and mass production of various products for automotive, industrial control and consumer applications. We follow strict design specifications and conduct testing and verification in UL-approved professional laboratories and equipment.

Prototype Production

We have a comprehensive parts procurement platform, providing multiple supplier platforms and material status services to grasp the quality and delivery of incoming materials accurately and to obtain sample confirmation from customers as fast as possible.

Customer Validation

Provide product specifications and sample functional test reports according to customer needs before mass production for customers to confirm sample specifications and functional performance.

Quality Control

Smart SMT Reel Storage System for systematic material management, material first in first out, inventory level indication, paired with automated testing and complete production history management services.

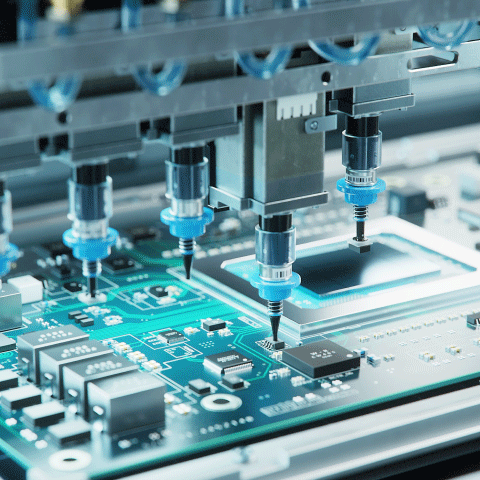

PCBA Mass Production

We use advanced equipment from Japan and Germany and AOI Inspection mechanism, and introduce automatic production equipment to improve the direct rate of customer products, and strictly control the production quality and efficiency.

After Sales Service

We share industrial control equipment channels resources, and having sales offices in north, central, south and east, providing a strong “One Day Taiwan” service team.

Customer Needs

Design and Development

Prototype Production

Customer Validation

Quality Control

PCBA Mass Production

After Sales Service

Soldering Paste Printer (YAMAHA YCP-10)

The maximum PCB size is supported to L510mm x W460mm, the minimum support is to L50mm x W50mm, the printing accuracy is ±0.025mm, and the repeat alignment accuracy is ±0.005mm. Use vacuum technology to make solder paste printing more precise and reduce the problem of excess amount of solder paste applied.

Dual track high speed Surface Mount System Mounter(YAMAHA YSM-20R)

Compatible component size 0201~W50mm x L100mm, PCB Max. W490mm x L810mm.

Soldering Paste Inspection Machine SPI(SINIC-TEK InSPIre-510b)

Min. inspection element: 01005 (imperial), Max. inspection height: +/- 450um.

AOI Inspection(YAMAHA YSI-V)

In-line 3D AOI can perform full product inspection to automatically identify errors in component position, component orientation and polarity.Resolution: Visible light (red/green/blue) and infra-red (12μm).

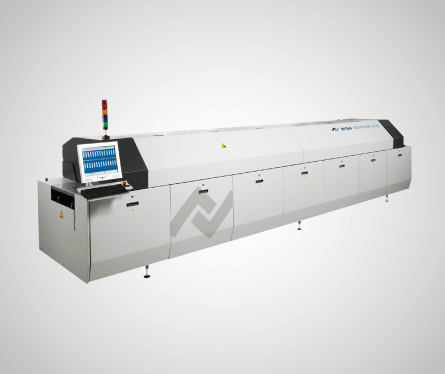

Reflow(ERSA Hotflow 3/20)

Patented temperature control technology, 10-zone temperature design for more accurate temperature curve, with full nitrogen process to enhance the saturation of the solder joints and improve product quality.Temperature zone: 10 ZONE up and 10 ZONE down Reflow method: multi-point nozzle for more accurate temperature curve.

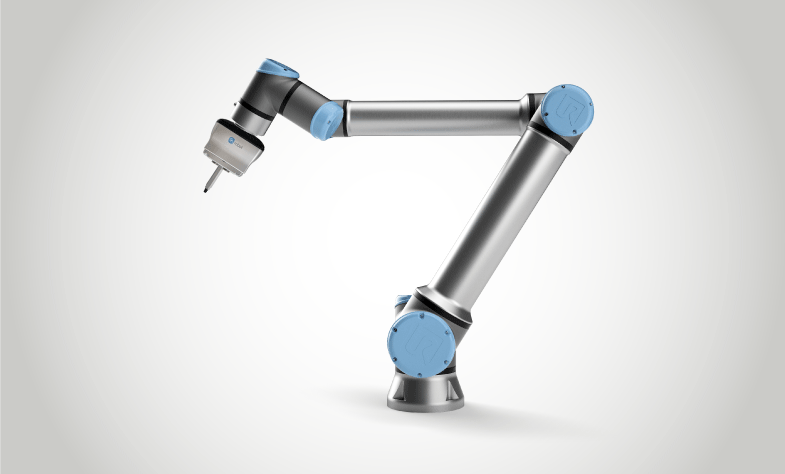

Smart Robot Arm(UR Robot UR10e)

6-axis collaborative robot arm can collaborate with PCBA manufacturing process to stabilize the quality of production, with a weight of 12.5kg, and with process integration optimization, such as: loading and unloading collaboration.

SMT Reel Storage System(Rhymebus SMTRS)

Combined with ERP system and database, it can effectively control each supplier’s customer-supplied materials, and connect to SMT machines to actively provide the quantity of remaining materials, with complete access to material records, and can be traced back to the source.

Excellent Manufacturing Capability

-DIP plug-in assembly

-Complete machine assembly

-Circuit board surface coating

-Uderfill

-Traceability and error prevention control

-PFMEA: Process Failure Mode and Effects Analysis