Energy Saving Solution for Hydraulic Oil Tanks

Energy Saving Solution for Hydraulic Oil Tanks

Traditional hydraulic oil tanks supply oil at a constant speed. When the pressure of the hydraulic cylinder is higher than the pressure-relief valves or during the holding process, amounts of oil flow back to the oil tank. This leads to energy consumption in the oil tank and increases the oil temperature.

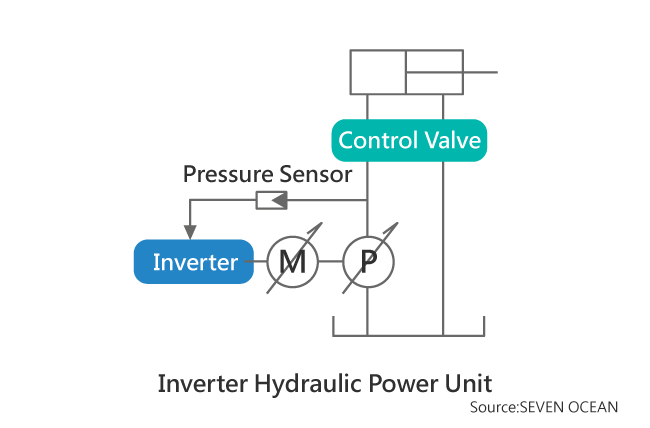

Adding a drive to the oil pump will maintain the oil pump at a stable pressure control, providing necessary flow according to the load variation.

The oil tank works with a high-efficiency motor and plunger pump, with an additional inverter and pressure sensor for customized oil flow. During the holding process, it keeps the pressure running at a low speed to achieve energy savings.

Advantage

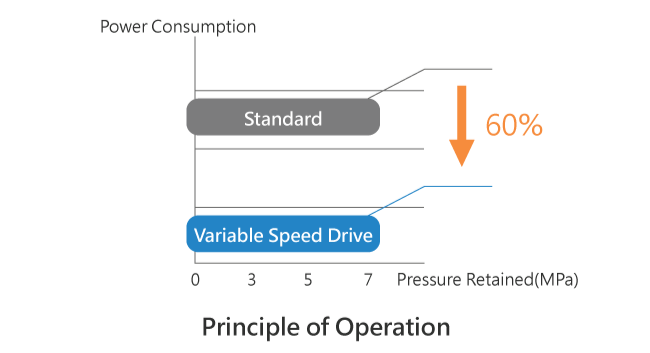

2. Consistent flow achieved by fixed pressure control. Minimizes motor operation through pressure control, saving energy up to 60%.

3. Reduces energy consumption by operating at low speed, resulting in low noise (15 dB).

4. Maintains the oil temperature at +2°C above room temperature by keeping a constant pressure (6MPA).