High Efficiency Air Conditioning System Energy Saving Solution

High Efficiency Air Conditioning System Energy Saving Solution

The equipment that consumes the most power in the air conditioning chiller system is the water-side system (including chiller, chilled water pump, cooling water pump, and cooling water tower). Generally, the power consumption of the water-side system accounts for about 50% to 60% of total electricity consumption of air conditioning system, and the performance of the central air-conditioning system is controlled by the mutual cooperation of chiller, water pumps, cooling water towers. The load of the air-conditioning system is not fixed. The cooling demand of the building will vary from 25 to 100% due to different climates, sunshine and the amount of internal heat sources. In the past, the control method of traditional air conditioning system drived the compressor, water pump and fan at a fixed speed and could not adjust the cooling capacity in response to the change of heat load, resulting in a lot of energy waste. Therefore, the frequency control has become an indispensable key technology in today's air conditioning system.

1. Chilled Water Pump Inverter Control

2. EnergySaving Control of Cooling Water Tower Fan

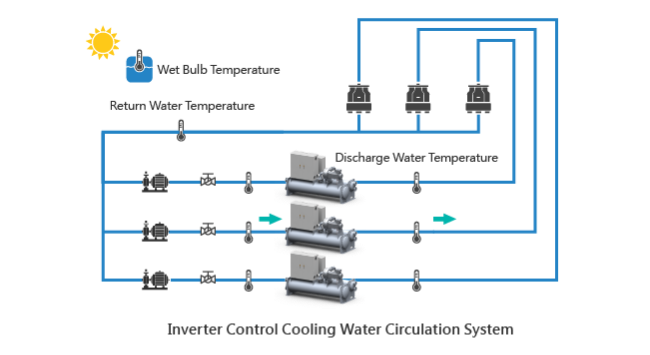

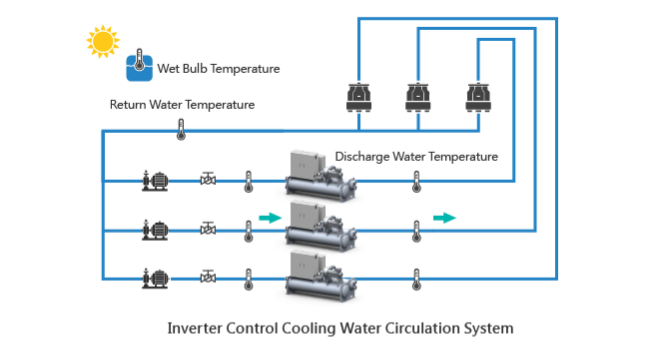

We adjust and control target temperature according to the external wet bulb temperature, and the cooling water temperature in the tower to the inverter is fed back to the inverter. PID control lowers the cooling water tower fan speed. According to the similar law, the fan power consumption of the water tower will also be reduced by the third power of the speed reduction, so as to achieve the purpose of energy saving.

3. EnergySaving Control of Cooling Water Pump

The temperature difference between the cooling water outlet and the return water of the chiller is used to control the cooling water pump to achieve the purpose of speed reduction and energy saving.

If the temperature difference is large, the speed of the cooling water pump should be increased to increase the circulation speed of the cooling water. If the temperature difference is small, the speed of the cooling water pump can be reduced to slow down the circulation speed of the cooling water.

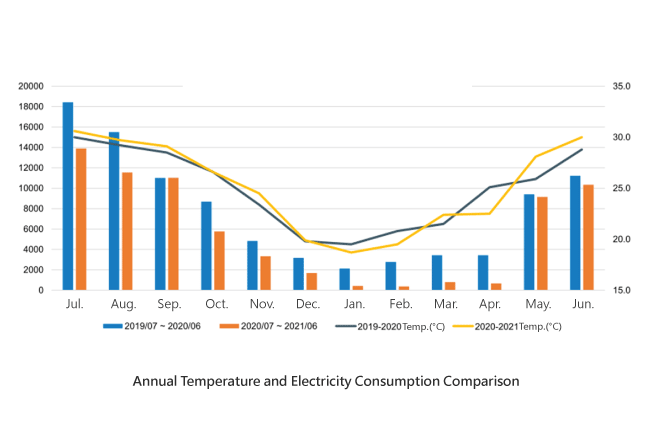

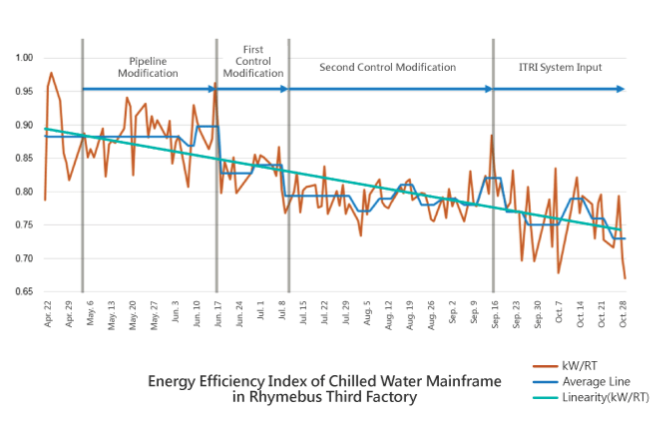

Example of Energy-Saving Improvement of Air Conditioning in Rhymebus Third Factory

1. Pipeline Lift Loss Improvement

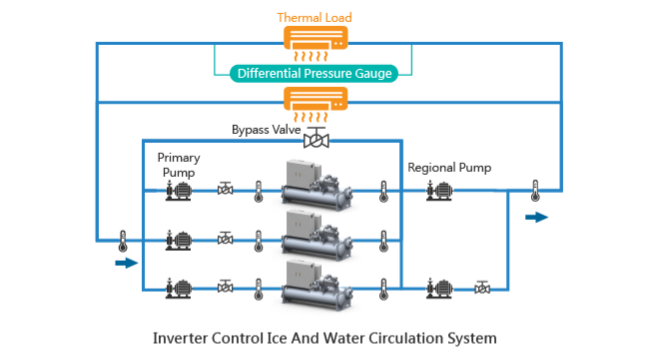

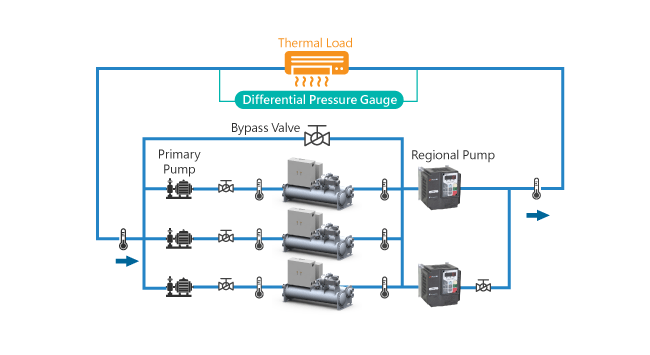

2. Ice Water Pump Inverter Control

Control objective: to provide the differential pressure required by the end heat load.

3. Cooling Water Pump/Fan Inverter Control

B. Cooling water pump speed is controlled by temperature difference signal of atmospheric wet bulb/return water temperature. Control objective: temperature difference 2~3°C.